Wattle & Daub: Craft, Conservation & Wiltshire Case Study

Contents

Contents

2 History

3 Craft

3.3 Panel Types

3.4 Staves

3.6 Daub

3.7 Decoration

4.1 Soils

4.1.1 Constituents

4.1.2 Plasticity

4.1.3 Strength

4.1.4 Field Testing

4.1.5 Selection

4.2 Dung

4.2.2 Lignin

4.2.3 Urine

4.2.4 Microbial Debris

4.2.5 The Role of Dung

4.3 Fibre

5.2.3 Maintenance

5.3 Repair

5.3.1 Partial Renewal

5.4 Replacement

5.4.1 Brick Infill

5.4.2 Renewal

6.3 Fieldwork

6.5 Evaluation

| Title Page Previous Next | Craft >Staves |

3.4 Staves

The staves were usually oak, but hazel, holly, birch, alder

and ash were also

used.[26]

Chestnut was quite durable but use was limited since supply was generally

restricted to the southeast. The staves were either selected as coppice in the

round or riven from the heartwood of larger timbers.

For wattle panels it was important that the staves were of the correct thickness so that the withies or laths could be easily worked around them without splitting or creating a panel that was too thick, as this would protrude too closely to the surface of the frame. Riven oak staves were usually 15-25mm deep by 60-90mm wide whereas hazel staves were typically 20-30mm diameter. Bark was often removed to reduce the risk of beetle attack. To assist weaving, the outside pair of staves was often thicker and shaped to a truncated wedged section and intermediate staves shaped to a truncated diamond section. This allowed each withy or lath to lie more flatly against the side of the stave, rather than touching just the protruding corners of an unshaped rectangular-sectioned stave. If nailed laths were to be used, the staves needed to be thicker, typically 50mm by 75mm and looking more like studs.[27]

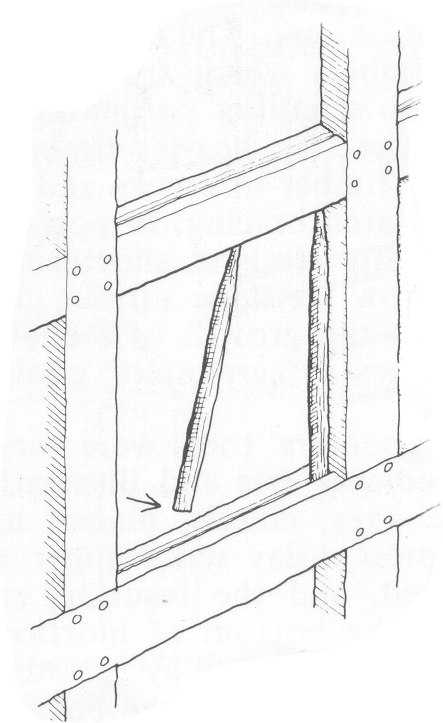

The tops of all staves were prepared to fit the underside of the rail. For an augered hole, they were roughly pointed by chamfering on all four sides or chamfered on just two sides to fit the width of a mortice. The bottoms were shaped to fit the groove in the lower rail by chamfering the front and back to almost a point, and the sides just slightly chamfered to allow the stave to be swung more easily into position [Figure 14].

[26]

Wright (1991), p.97.

[27]

Thompson (2003), p.1.