Wattle & Daub: Craft, Conservation & Wiltshire Case Study

Contents

Contents

2 History

3 Craft

3.3 Panel Types

3.4 Staves

3.6 Daub

3.7 Decoration

4.1 Soils

4.1.1 Constituents

4.1.2 Plasticity

4.1.3 Strength

4.1.4 Field Testing

4.1.5 Selection

4.2 Dung

4.2.2 Lignin

4.2.3 Urine

4.2.4 Microbial Debris

4.2.5 The Role of Dung

4.3 Fibre

5.2.3 Maintenance

5.3 Repair

5.3.1 Partial Renewal

5.4 Replacement

5.4.1 Brick Infill

5.4.2 Renewal

6.3 Fieldwork

6.5 Evaluation

| Title Page Previous Next | Craft >Daub |

3.6 Daub

The term to daub

derives from the Old French term dauber

meaning to plaster, paint or whitewash: the roles of plasterer and whitewasher

were closely related. The modern meaning of “to dab” is probably

derived from the act of daubing clay earth onto buildings. The modern sense of

doing a job clumsily or crudely is not without relation to the processes of

daubing infill panels since the initial placement of the clay onto the wattle is

not a precise craft. Success is more reliant upon careful preparation, detailing

and aftercare of the daub.

As an unbaked earth, daub shared much in common with solid earth walling such as cob, pisé and clay lump, yet the primary difference was that daub is non-structural and hence was less precise. There were, however, variants that fell between the two such as ‘stud and mud’ walls. These had vertical timber studs between which solid earth was rammed to provide load-bearing assistance to the structural timbers. However, only daub is considered here.

Daub was principally earth. Not any earth was suitable, since it had to be generally free from organic topsoil, contain some clay as a binder, yet also contain sandy aggregate so not be too clayey, as otherwise the daub would shrink excessively. It is generally accepted that the dauber would use the earth immediately surrounding the building and so the daub mirrored the local geology. Since the practice spanned many geological areas, the types of earth varied greatly. However, Warren (1999) claims that if the earth was unsuitable then materials may have been transported significant distances.

To enhance the performance of a daub it was usual for the dauber to add dung, fibre and to mix various earth types. The determining factor in selection of materials was probably more related to what was readily available rather than any specific regional variation. In 1530 it was written,

As an unbaked earth, daub shared much in common with solid earth walling such as cob, pisé and clay lump, yet the primary difference was that daub is non-structural and hence was less precise. There were, however, variants that fell between the two such as ‘stud and mud’ walls. These had vertical timber studs between which solid earth was rammed to provide load-bearing assistance to the structural timbers. However, only daub is considered here.

Daub was principally earth. Not any earth was suitable, since it had to be generally free from organic topsoil, contain some clay as a binder, yet also contain sandy aggregate so not be too clayey, as otherwise the daub would shrink excessively. It is generally accepted that the dauber would use the earth immediately surrounding the building and so the daub mirrored the local geology. Since the practice spanned many geological areas, the types of earth varied greatly. However, Warren (1999) claims that if the earth was unsuitable then materials may have been transported significant distances.

To enhance the performance of a daub it was usual for the dauber to add dung, fibre and to mix various earth types. The determining factor in selection of materials was probably more related to what was readily available rather than any specific regional variation. In 1530 it was written,

‘daubing may be with clay onely, with lime plaster,

or lome that is tempered with heare or

strawe’.[37]

The desire to strengthen the daub with fibre seemed to be

sufficiently important for materials to be bought

in.[38]

The straw, hay, or occasionally flax stick reed, was usually chopped to enable

workable amounts to be extracted from the mass. Fibre may also have helped

reduce the weight of the

material.[39]

Straw was the most usual, flax stick being more frequently adopted in the

Midlands. The stick was the inner stem that remained after removal of the outer

fibre that was taken to produce

linen.[40]

The daub was mixed by foot or by ox hoof.[41] Manure was commonly added to make the earth workable in preference to water that would result in excessive shrinkage. It has been said that the introduction of dung may have been accidental as a result of using oxen, but since its use was so regular and is frequently mentioned in historic texts it is likely that its inclusion was intentional. A few references are made to the use of horse manure, but this variation may only have developed as the use of horses in agriculture became widespread during the 17th and 18th centuries.[42] The addition of salt to retard drying and gauging with lime are also known.[43]

To apply the daub, it was common for a small palm-full, or ‘cat’, to be pushed into the wattle. This work would usually be done from both sides of the wall simultaneously. Alternatively, a wetter daub could be thrown onto the wattle in a similar way that a render was often hurled rather than trowelled.

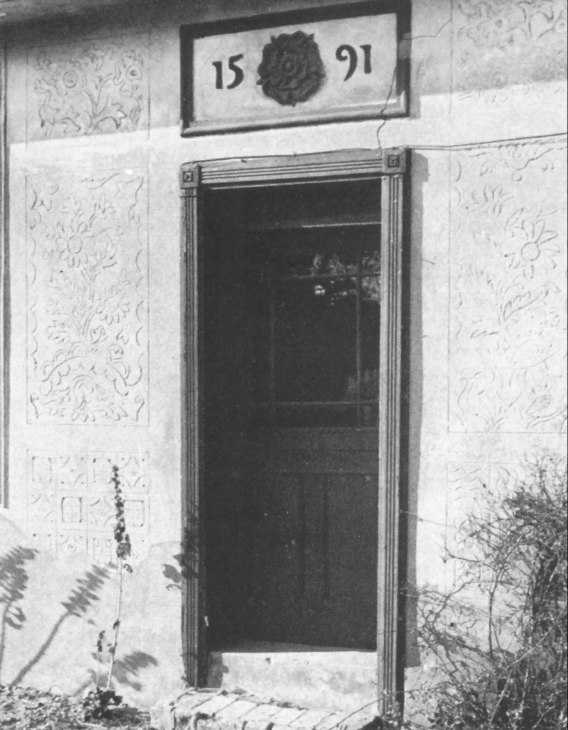

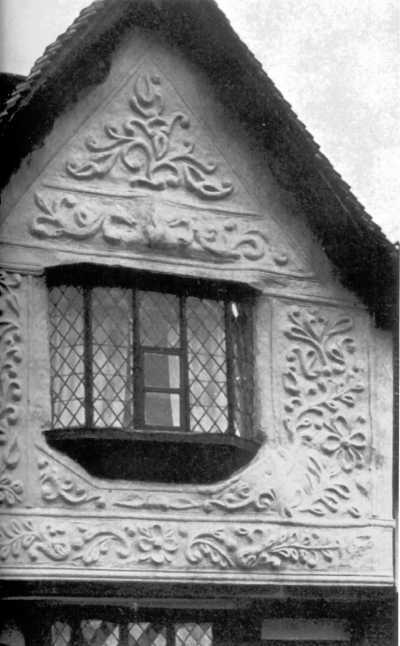

Figure

19. The daub of sheltered internal partitions was often

crudely finished, with cracking left unattended.

The finish to panels varied greatly. The simplest was

nothing more than a limewash. In this case the surface of the daub was either

slightly recessed at the edges of the panel or finished flush and its surface

crudely smoothed. For exterior work, the inevitable cracking would have to be

reworked whilst semi-dry or filled with extra daub before limewashing.

Durability was frequently improved by coating with plaster since it filled any

cracks and could be worked into the gaps which would consistently appear around

the panel edge due to shrinkage of the daub. The surface of the daub was often

keyed using a lath scratcher or dimpled with the end of a lath or withy. The

plaster applied to this varied by region, either being plain sand:lime, with

gypsum or earth-based and may have also included dung, hair or

straw.[44]

Invariably the panel was finished with limewash.

Where the work was hidden and was not to be exposed to the

weather, such as in roof truss partitions, the evidence of large cracks suggest

the dauber readily accepted the crude finish and did little to rework the panels

[Figure 19].

The above descriptions of daub arise from historic texts or visual interpretation. Scientific analyses of the constituents of historic daub are sparse with the only reliable published results coming from English Heritage’s Research Technical and Advisory Services (RTAS) of the mid 1980’s in which samples from the Weald were investigated.[45] The results, although of small sample size, provide details of the types of earth and additives used in that region. All earths analysed were found to contain a small proportion of clay (5-10%), mainly comprising silts and fines and some with larger aggregate including flint and chalk. Additives found were dung, grass (hay) and animal hair. There was no evidence of gauging with lime.

The above descriptions of daub arise from historic texts or visual interpretation. Scientific analyses of the constituents of historic daub are sparse with the only reliable published results coming from English Heritage’s Research Technical and Advisory Services (RTAS) of the mid 1980’s in which samples from the Weald were investigated.[45] The results, although of small sample size, provide details of the types of earth and additives used in that region. All earths analysed were found to contain a small proportion of clay (5-10%), mainly comprising silts and fines and some with larger aggregate including flint and chalk. Additives found were dung, grass (hay) and animal hair. There was no evidence of gauging with lime.

|

|

||||||

|

|

|

||||||

|

|

|

||||||

|

|

||||||

|

|

|

|

|

||||

[37]

Salzman (1952), p.190.

[38]

Forrester (1959), p.35. Also, in 1286 ‘white straw’ was bought for

Cambridge Castle; in 1375 eight loads of straw for Leeds Castle; in 1477 at Bath

the churchwardens of St. Michael’s bought hay and straw for daubing; and

in 1491 at St. Mary-at-Hill in London they bought ‘strawe to make mortere

with to the dawbere’. (Salzman, 1952:

191).

[39] Wright (1991), p.98.

[40] Powys (1929), p.66.

[39] Wright (1991), p.98.

[40] Powys (1929), p.66.

[41]

This is widely stated, such as by Wright (1991), Salzman (1952), Harrison (1999)

and

others.

[42] Horse manure is mentioned by Thompson (2003) and inferred by Ashurst and Ashurst (1988a).

[43] Ashurst and Ashurst (1988a), p.117.

[42] Horse manure is mentioned by Thompson (2003) and inferred by Ashurst and Ashurst (1988a).

[43] Ashurst and Ashurst (1988a), p.117.

[44]

Reid (1989), p.2.

[45]

Ashurst and Ashurst (1988a), pp.121-126.